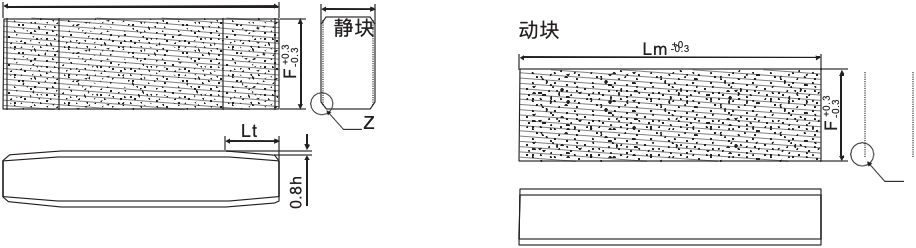

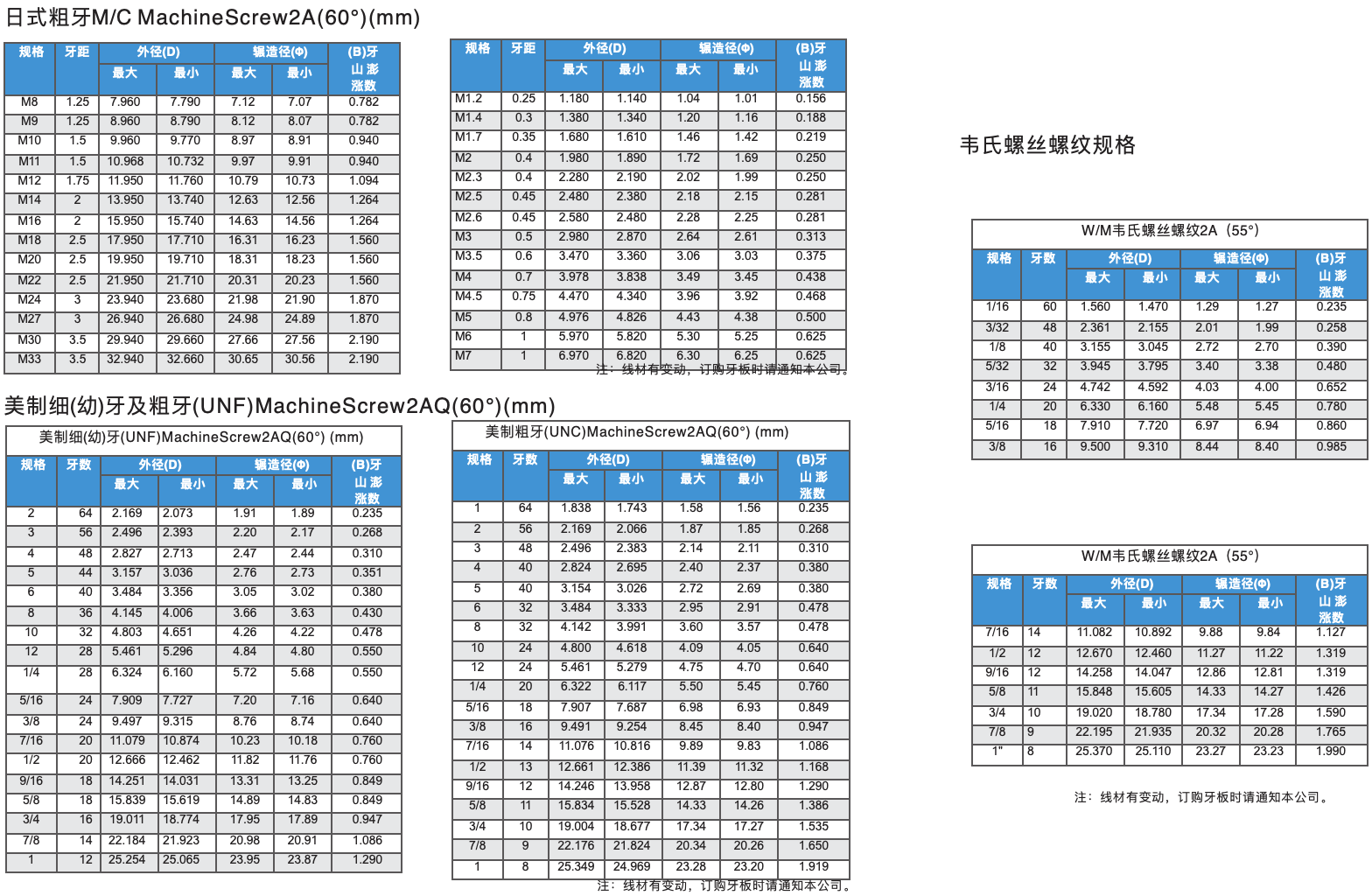

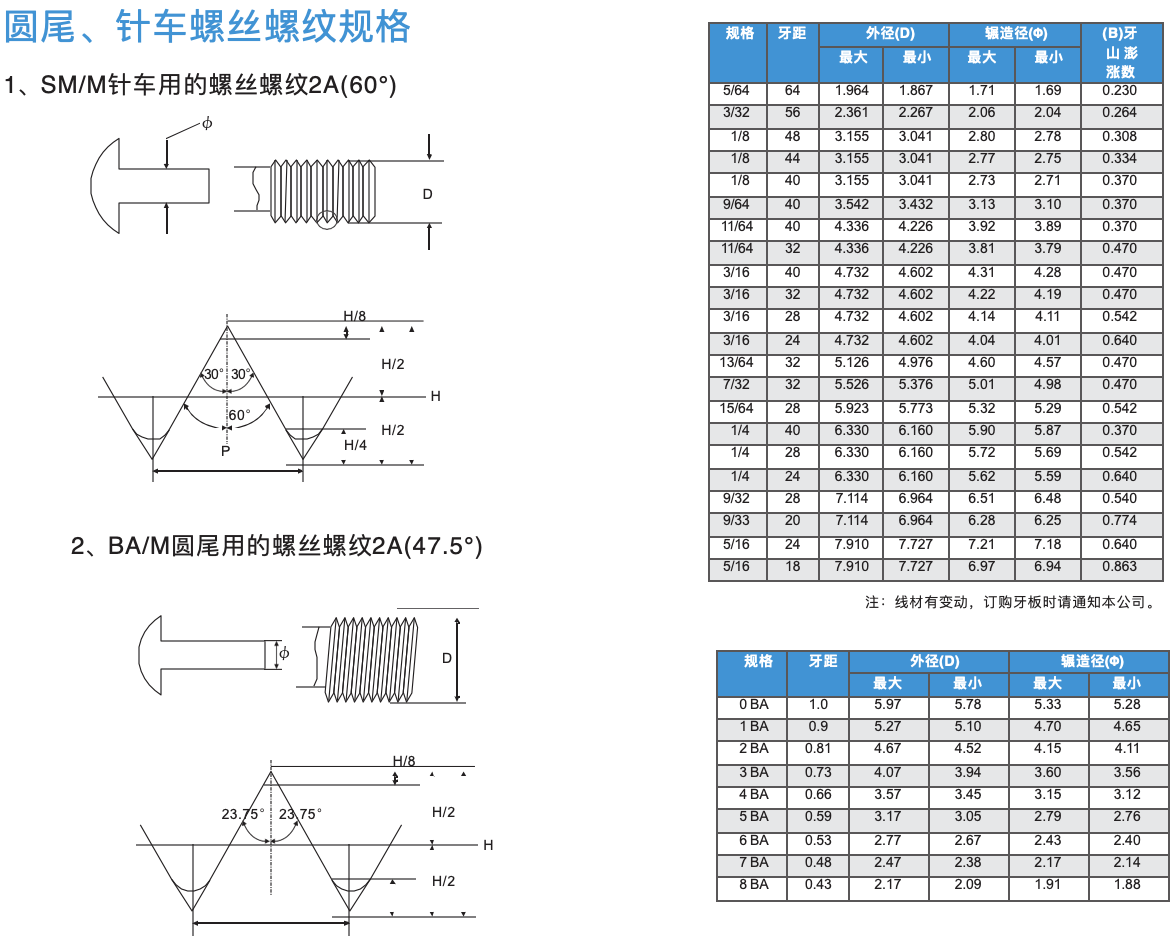

Standard working drawing of thread rubbing board

client's name | Rubbing board material | tool steel | |

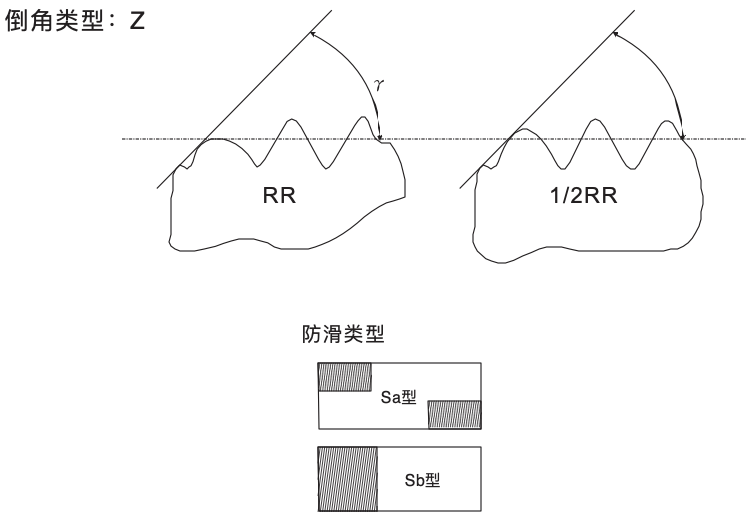

Drawing Numbers | Chamfer type | 1/2RR | |

cartographer/date | Pressure plate type | Machine tooth double-sided standard | |

Check/date | Anti-slip type | ||

Review/date |

mark | LS | H | 0.866P |

LM | h | 0.6143P | ||

D | a | H/8 | ||

F | b | H/6 | ||

LT | ω | 60° | ||

P | ν | 30° |

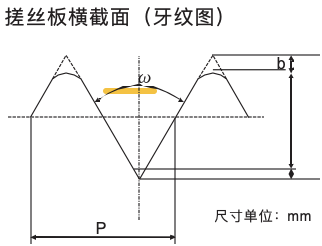

Overview of triangular thread

(one)Advantages of triangular thread

1、Reduce additional tapping processes and related costs。

2、Triangular tooth design provides anti-loosening effect,Reduce the requirements for anti-loosening gaskets and adhesives。

3、Due to the rigid stress on the mother piece during tapping, strong inter-tooth tightness is produced。

4、Allows for larger variation in mother piece aperture。

5、Can be used for a variety of materials and various types of punching、Drill、cast、Extrusion molding holes。

6、After using high frequency local carburizing heat treatment, Can handle thicker deep-hole steel parent parts while retaining the toughness of quenching and tempering heat treatment Spend。

7、The mother part with paint glue or welding slag can still be tapped.。

8、Will not cause tooth interference。

9、Preset torque always equals or exceeds self-locking screw standards。

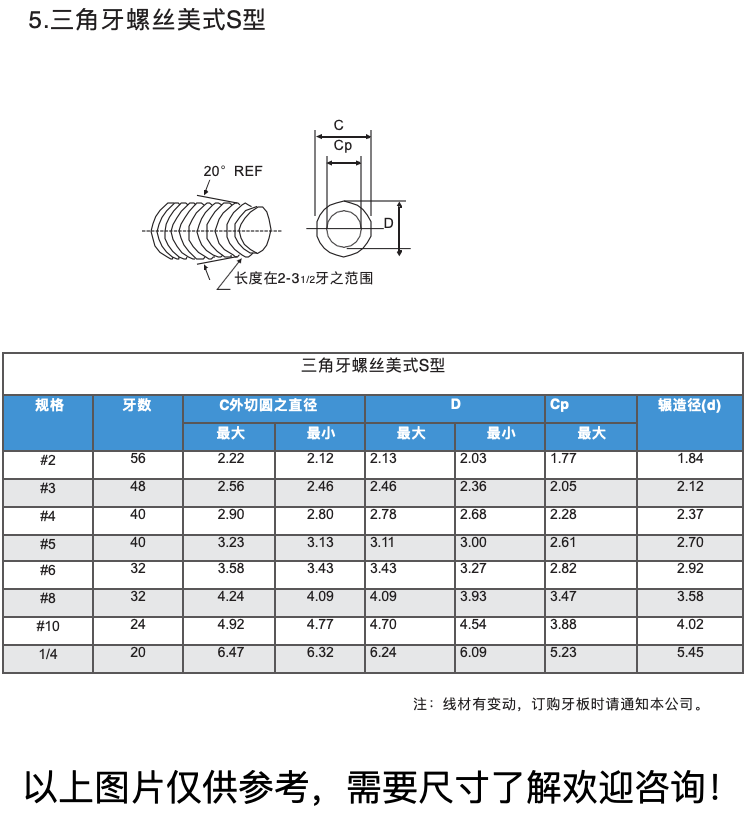

(two)There are four types of triangular self-tapping screws

1、S TYPE:General mechanical teeth、After the triangular screw is withdrawn,Interchangeable with small screws that meet its specifications。

2、C TYPE:with small screws andC TYPEThe same as the iron die,And can be used with nuts。

3、B TYPE:andB TYPEThe same as the iron die,Suitable for use on thin iron plates and plastics。

4、P TYPE:Used in plastic plastics。

three)Comparison between general screws and triangular screws

1、After tapping and locking, the peak of the thread swells to the bottom of the screw, making close contact and making it difficult to loosen.,And it is not necessary to drill deep。

2、Cut off the tailBType iron plate screw cutting and locking,Its tightness is no better than(1)high,And the drilling should be deep enough to cut slag。

3、First twist the teeth and then lock the small screws in, but the tightness is not good.,Requires spring washers or nuts included。

4、Striangular screw,Tapping and locking into the tooth peak,Pine that does not stick to the bottom of the tusk,No need to match pads and nuts。

Four)The use of triangular screws

In electrical products、Transportation equipment、household items、precision machine、A wide range of toy plastics and die-cast parts